What is UHMWPE rope?

UHMWPE is a safer alternative to wire rope and is better value for money. It is an extremely high-strength, lightweight, heat-treated rope. With a high abrasion resistance and low stretch ability, our 12 strand Stealth Fibre® UHMWPE is appropriate for many industrial operations. At larger diameters, this rope falls into a high price bracket due to its superior properties.

What does UHMWPE stand for?

UHMWPE is used in high-performance lines across a variety of industries, including marine, commercial fishing, mountaineering, and aquaculture. It has many qualities that make it an excellent choice for wet environments; it is light enough to float, is hydrophobic (repels water) and stays tough at low temperatures. You will also find it used in yachting, particularly with sails and rigging, as its low stretchability lets the sails maintain an optimal shape while still being exceptionally resistant to abrasion.

With its high strength to weight ratio, smooth handling and low stretch properties, it is the rope of choice for ship assist lines, offshore rigs and tankers. It is especially popular for manoeuvring vessels in distress situations.

Our UHMWPE rope exceeds ISO 10325 standards, is competitively priced and comes with free delivery in the UK, so contact us today with your needs.

What are the properties of UHMWPE?

The superior properties of UHMWPE include:

- High melting point (over 144°C)

- Low density – floats on sea water

- Low weight

- Safer than wire – breaks in a linear fashion

- High performance

- Low moisture absorption (repels water)

- Chemical resistant (excluding oxidising acids)

- High strength – stronger than hardened steel

- UV resistance – prolonging the life of your rope

- Self-lubricating – low coefficient of friction

- Superior abrasion resistance

- Ultra-low stretch (3–4% at breaking load)

- Reduced cost in comparison to steel rope

- Low dielectric constant – almost transparent to radar

- Vibration damping

- Low maintenance

- Low electrical conductivity

- Excellent flex fatigue

These high-performance ropes are increasingly being used to replace steel and conventional fibres. They are significantly stronger than steel yet only 1/8th of the weight of comparable steel wires. In other words, they are at least 8 times stronger than steel wire ropes.

Ultra high molecular weight polyethylene (UHMWPE) lines are thinner, lighter and self-lubricating, so significantly more practical to handle than conventional steel ropes. In addition to their strength, they are also much safer, with less recoil force than a steel rope. When a steel rope breaks, the metal wire unravels quickly, leaving razor-sharp edges whipping around unpredictably. When a UHMWPE rope breaks, the recoil is much less. Thanks to its construction of long chains of polyethene aligned in the same direction, if it breaks (which is unlikely due to its bond strength), the rope will display a linear, predictable recoil.

The self-lubricating fibres of UHMWPE also tend to have a waxy handle and smooth surface, making them easy to handle, although this means it does not hold knots particularly well. Yet despite their smoothness, they are still at least 15 times more resistant to abrasion than carbon steel.

Lastly, in comparison to steel rope or other polyester ropes, UHMWPE ropes are smaller in volume due to the smaller quantities needed to achieve the same outcome. This makes them easier to store.

How is UHMWPE manufactured?

As mentioned, UHMWPE is a polyolefin fibre. The fibres are produced through a gel spinning process of a polyolefin resin (HMPE) with an exceptionally high molecular weight, usually between 2 and 6 million g/mol. With the aid of a solvent, the resin is transformed into a gel solution. Fibres are spun from this high molecular weight solution, the solvent removed, and the polyethylene fibre stretched to many times its original length. The result is a very tough material, with the greatest impact strength of any thermoplastic currently in circulation.

Why should UHMWPE be considered?

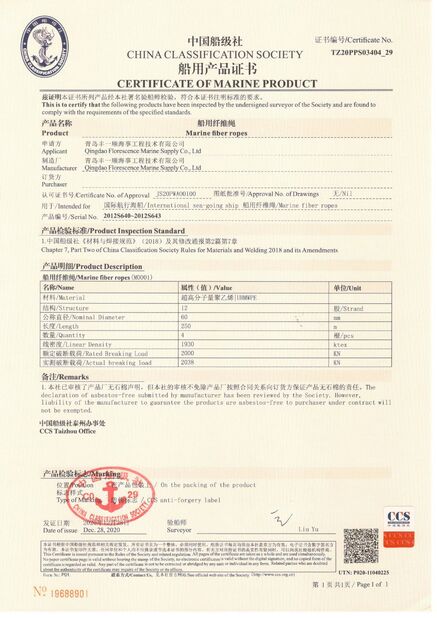

Thanks to its unique properties, Ultra High Molecular Weight Polyethylene can be used in a variety of operations where strength is needed. It is also an ideal solution for many marine applications. The ropes are also widely used and accepted by the major classification societies. UHMWPE rope is included in the OCIMF’s Guide to Purchasing High Modulus Synthetic Fibre Mooring Lines.

UHMWPE cord is designed to overcome four key challenges common in mooring, towing, winch rope and heavy-duty lifting rope. These are abrasion resistance, bending-fatigue, compression and creep-fatigue.

1. Abrasion resistance

UHMWPE ropes have an abrasion lifetime that is up to 4 times greater than steel wire rope and rope made from regular HMPE and polyester. As such, it is an excellent, long-lasting investment. In mooring, arborist, and lifting operations, the rope will often come into contact with uneven, rough surfaces. Over time, this can wear away at the fibres, impacting their strength, performance and safety. Our UHMWPE high-performance ropes can withstand much of this abrasion.

2. Bending and compression fatigue

Bending fatigue occurs whenever a line flexes or bends under tension. Compression fatigue occurs when the line is compressed. Both of these can wear out the rope, reducing its lifetime, and should be taken into consideration in high-load situations.

As previously mentioned, UHMWPE rope is made up of long chains of overlapping polyethene fibres. This construction means that compression and bending fatigue are considerably less than in synthetic and steel equivalents.

3. Creep-fatigue

Creep-fatigue happens when a rope elongates in high temperatures. Over time, it can lead to catastrophic failure of the line and is a major risk in ropes made from normal synthetic fibres or regular HMPE (high modulus polyethylene). Because our 12 strand single braid Stealth Fibre® UHMWPE (Ultra-high molecular weight polyethene rope is heat-treated and has a polyurethane coating, it has a creep lifetime up to 4 times greater than generic HMPE rope.

4. Handling

Wire rope can be cumbersome to handle and requires significant logistical operations to transport it. UHMWPE has an impressive strength to weight ratio, is 1/8th of the weight of steel wire rope and can be up to 15 times stronger. This makes it an excellent wire rope replacement. As it is also self-lubricating, it is much easier to handle on a regular basis.

What is UHMWPE used for?

Typical applications of Ultra high molecular weight polyethylene (UHMWPE) include:

- Towing heavy objects, especially vehicles and vessels

- Winching, both onshore and offshore

- Mooring – it is recommended by OCIMF for safe mooring of tanker vessels

- Cranes and pulley systems where heavy lifting is required

- Wire rope replacement – it is stronger and more affordable

- Anchor rope

- Deepwater installations

- Lifting slings and cables

- Paragliding lines

- Trawl nets and ropes

- Synthetic link chains

- Pulling up the mainsails of yachts

- Kickers – for pulling on tension on the sail and boom

- Strops – replacing sail ties to connect the sail to the boat

- Conveyor lines

- Fishing lines –

- Spear lines on spear-guns

- Watersports (wake-board and kite surfing lines)

- Marine equipment

- Operations that require regular harsh cleaning in a wet environment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!